Roller Sizer

The roller sizer automatically classifies the fruit according to its size, weight, or shape, optimizing the selection process and facilitating uniform packaging. We manufacture custom-made roller sizers, adapted to the characteristics of the product and each client’s workflow, guaranteeing precision and efficiency throughout the process.

STAINLESS STEEL WASHING MACHINE

The stainless steel washing machine is a machine designed for the post-harvest treatment of fruits, vegetables and vegetables, especially citrus fruits. Its main function is to carry out a complete and effective cleaning of the fruit, removing dirt, impurities and residues prior to waxing, calibrating or packaging.

The system incorporates nylon brushes, natural hair brushes and latex washers, which ensure deep cleaning and correct water draining. In addition, it has a foam dispenser and pressurized water showers, which allow uniform washing over the entire surface of the fruit.

The machine is completed with an outlet extractor, which facilitates the continuous evacuation of the fruit to the next phases of the line. Its stainless steel construction guarantees durability, resistance to moisture and optimal hygiene in intensive use.

.

FEATURES

| Installed Power: | 2.2 kW |

| Voltage: | 380/220 V III [Single Phase on Demand] |

| Production [width 2000mm]: | 25 Tm/h |

| Production [width 1500mm]: | 20 Tm/h |

| Production [1000mm]: | 15 Tm/h |

| Main Function: | Post-harvest washing of fruits and vegetables |

| Brush: | Nylon and natural hair brushes |

| Water Disposal: | Latex washers |

| Washing system: | Foam dispenser + pressurized water showers |

| Construction material: | Stainless steel (structure and main components) |

| Fruit output: | Integrated exhaust fan |

| Application: | Citrus fruits and other fruits/vegetables of various shapes and sizes |

| Online Integration: | Compatible with drying tunnels, wax applicators and calipers |

DRYING TUNNEL

The drying tunnel is a machine designed for the post-harvest treatment of fruits, vegetables and vegetables, especially citrus fruits. Its main function is to carry out the uniform pre-drying and/or drying of the fruit, ensuring proper treatment before processes such as waxing, calibrating or packaging.

The system is made up of motorized galvanized rollers, which transport the fruit along the tunnel while a controlled flow of hot air is applied. Drying is carried out by indirect combustion generators and air fans, which guarantees efficiency, safety and a homogeneous result without damaging the product.

This equipment is robust, reliable and easy to integrate into fruit and vegetable lines, providing a continuous and stable drying process with low maintenance.

FEATURES

| Installed Power: | 4 Kw |

| Consumption: | 8/9 litres/hour [FUEL] [GASOIL] |

| Voltage: | 380/220V IIi [220 V Single Phase On Demand] |

| Production [width 2000mm]: | 25 Tm/h |

| Production [width 1500mm]: | 20 Tm/h |

| Production [1000mm]: | 15 Tm/h |

| Main Function: | Pre-drying and/or drying of post-harvest fruits |

| Transport system: | Motorized galvanized rollers |

| Drying system: | Indirect combustion generators + air fans |

| Application: | Citrus fruits, fruit and vegetables of different sizes |

| Construction: | Robust metal frame, easy cleaning |

| Online Integration: | Compatible with washing machines, wax applicators and calipers |

| Production: | Adaptable to different capacities according to need |

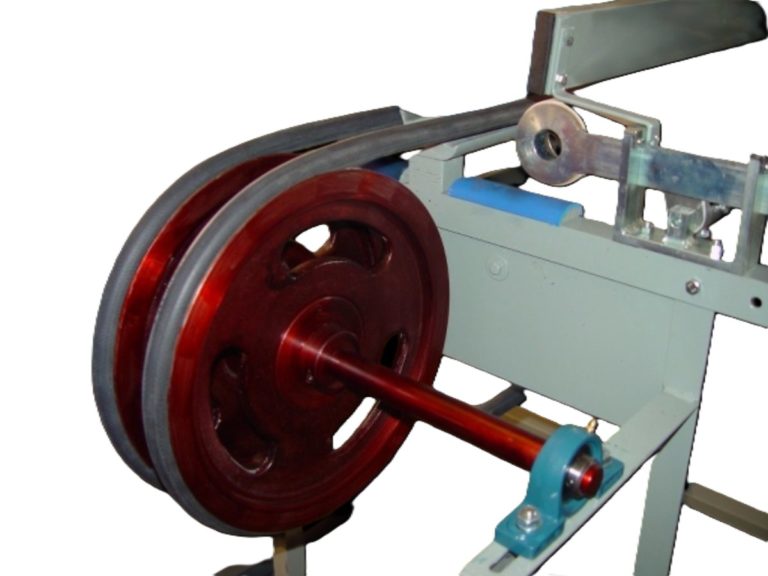

WAX APPLICATOR

The wax applicator is a machine designed for the post-harvest treatment of fruits, vegetables, and produce, especially citrus. Its main function is to ensure a uniform protective wax coating on fruits of different shapes and sizes, improving their preservation and commercial appearance.

The system operates with natural bristle brushes driven by transmission, which guarantee a smooth and even coating over the entire surface of the fruit. For wax application, it incorporates valves mounted on a reciprocating rail, which distribute the product consistently and precisely.

This equipment is designed for intensive use in fruit and vegetable packing houses, offering a reliable, efficient, and easy-to-maintain process.

FEATURES

| Installed Power: | 1.5 kW |

| Voltage: | 380/220V III [220 V Single Phase On Demanda] |

| Output [width 2000mm]: | 25 Tm/h |

| Output [width 1500mm]: | 20 Tm/h |

| Output [1000mm]: | 15 Tm/h |

| Main Function: | Uniform wax application on fruits |

| Application System: | Metering valves on a reciprocating rail |

| Brushing: | Natural bristle brushes with motorized transmission |

| Application: | Cítrus and other post-harvest fruits/vegetables |

| Working Capacity: | Adjustable according to fruit size and volume |

| Construction: | Robust metal structure, easy to clean In-line |

| Integration: | Compatible with washers, dryers and graders |