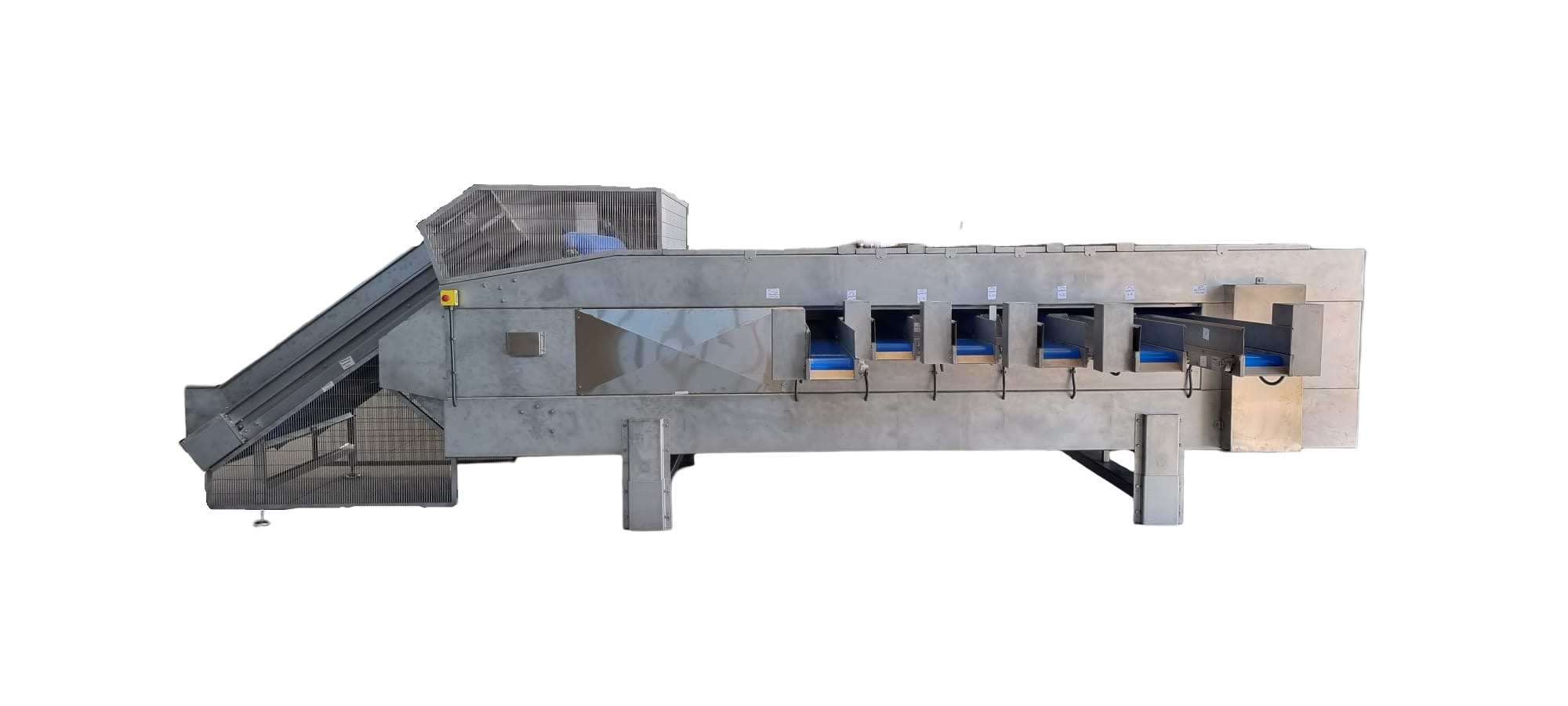

STAINLESS STEEL TILTING ROLLER SIZER

The stainless steel roller sizer is a machine designed for the post-harvest treatment of fruits and vegetables, especially citrus fruits. Its main function is to separate the fruit by size automatically, guaranteeing precision and care during the process.

The system is made up of paired stainless steel rollers that rotate continuously, keeping the fruit in rotation over its largest diameter. These rollers are progressively spaced, generating different openings that allow each fruit to fall at the right time towards the lower conveyors, separating in an orderly manner according to its size.

Thanks to its stainless steel construction, this calibrator complies with all hygiene and food safety regulations, being especially suitable for fruit and vegetable plants looking for reliability, durability and easy maintenance.

FEATURES

| Installed Power: | 2,2 Kw |

| Voltage: | 380/220V III [220V Single Phase on Demand] |

| Production [width 2000mm]: | 23 Tm/h (in Oranges) 17 Tm/h (Mandarins) |

| Production [width 1500mm]: | 18 Tm/h (in Oranges) 12 Tm/h (Mandarins) |

| Production [1000mm]: | 12 Tm/h (in Oranges) 9 Tm/h (Mandarins) |

| No. Of Departures: | On Request |

| Calibration system: | Tilting rollers in stainless steel Working |

| Working Principle: | Progressive separation by size, keeping the fruit in rotation |

| Application: | Citrus fruits, fruits and vegetables of different shapes and sizes |

| Production: | Adaptable to different volumes depending on configuration |

| Fruit output: | Controlled fall into trays or conveyors |

| Construction: | Robust metal frame and easy-to-clean components |

| Online Integration: | Compatible with manufacturing, packaging and sorting processes |

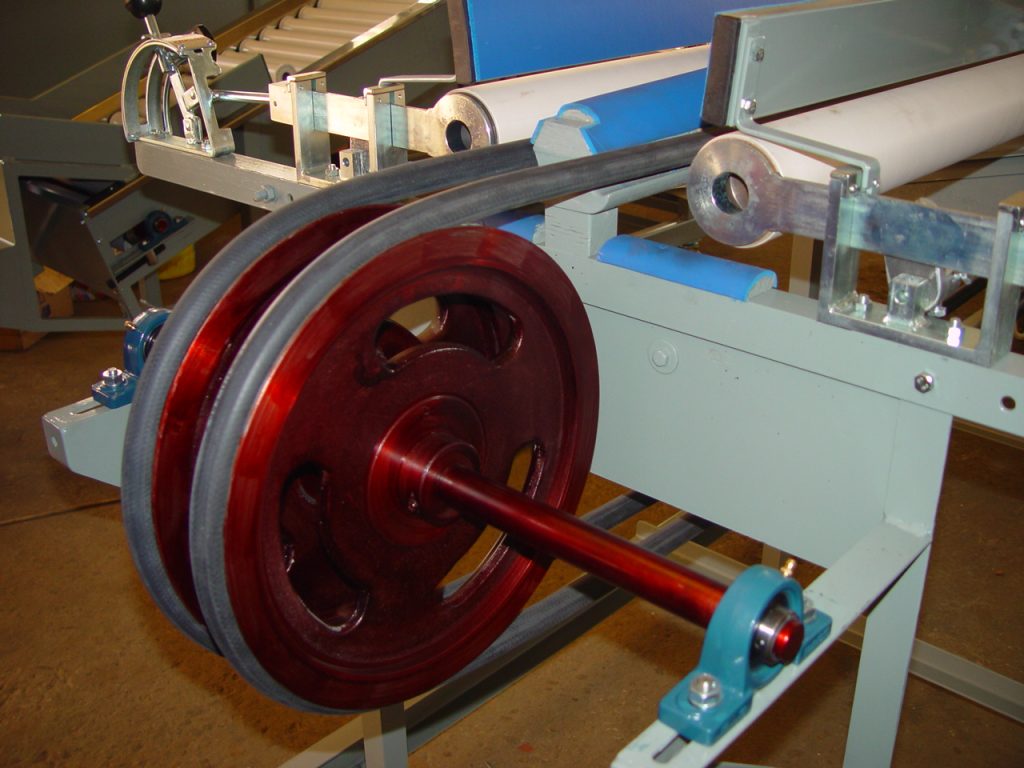

CENTRIFUGAL ROLLER SIZER

The centrifugal roller sizer is a machine designed for the post-harvest treatment of fruits, vegetables and vegetables, especially citrus fruits. Its function is to carry out the automatic calibration of fruits of different shapes and sizes, guaranteeing precision and care of the product.

The system is composed of an aluminum disc equipped with rubber segments, which keep the fruit in constant rotation on its largest diameter. As these segments progressively distance apart, each part falls at the exact point corresponding to its caliber, achieving a uniform and damage-free classification.

This model stands out for its robust design, low maintenance and ease of integration into fruit and vegetable lines, being a reliable and efficient solution for the calibration of citrus fruits and other products.

FEATURES

| Installe Power: | 0.37 kW |

| Voltage: | 389/220 V III [220 V Single Phase On Demand] |

| Production: | 1200 Kg/h |

| No. of Departures: | 7 Gauges |

| Calibration system: | Aluminium disc with progressive rubber rings |

| Working Principle: | Separation by size by gradual opening, keeping the fruit in rotation |

| Application: | Citrus fruits, fruits and vegetables of different shapes and sizes |

| Production: | Adaptable to different volumes depending on configuration |

| Fruit output: | Controlled fall into trays or conveyors |

| Construction: | Aluminium disc, rubber segments and robust metal structure |

| Online Integration: | Compatible with manufacturing, packaging and sorting processes |

TILTING ROLLER SIZER

The tilting roller sizer is a machine designed for the post-harvest treatment of fruits, vegetables and vegetables, especially citrus fruits. Its main function is to carry out the automatic calibration of fruit of different shapes and sizes, guaranteeing precision and care at all times.

The system is composed of paired rollers in galvanized steel, which rotate continuously and keep the fruit in rotation on its largest diameter. As the rollers progressively separate, each part falls at the point corresponding to its gauge, achieving a uniform and efficient classification.

This model is a robust, reliable and easy-to-maintain solution, especially suitable for fruit and vegetable plants looking for versatile and durable equipment for productions of different volumes.

FEATURES

| Installed Power: | 2,2 Kw |

| Production [width 2000mm]: | 23 Tm/h (in Oranges) 17 Tm/h (Mandarins) |

| Production [width 1500mm]: | 18 Tm/h (in Oranges) 12 Tm/h (Mandarins) |

| Production [1000mm]: | 12 Tm/h (in Oranges) 9 Tm/h (Mandarins) |

| No. of Departures: | On Request |

| Calibration system: | Tilting rollers in galvanized steel |

| Working Principle: | Progressive separation by size, keeping the fruit in rotation |

| Application: | Citrus fruits, fruits and vegetables of different shapes and sizes |

| Production: | Adaptable to different volumes depending on configuration |

| Fruit output: | Controlled fall into trays or conveyors |

| Construction: | Robust metal frame and easy-to-clean components |

| Online Integration: | Compatible with manufacturing, packaging and sorting processes |

CAB TILTING ROLLER SIZER

The tilting roller sizer is a machine designed for the post-harvest treatment of fruits, vegetables and vegetables, especially citrus fruits. Its main function is to classify the fruit automatically according to its size, guaranteeing precision and care during the process.

The system is composed of paired rollers in galvanized steel that rotate continuously, keeping the fruit in rotation on its largest diameter. These rollers are progressively spaced, allowing each piece to fall at the exact point towards the corresponding trays, where it is fitted in an orderly manner.

This model is specially designed for small productions, offering a practical, compact and efficient solution for fruit and vegetable plants that need to separate fruit of different sizes without sacrificing the reliability and robustness of an industrial system.

FEATURES

| Installed Power: | 2.2 Kw |

| Voltage: | 380/220V III (220V Single Phase on Demand) |

| Production (width 1000 mm): | 10 Tm/h (Oranges); 7 Tm/h (Mandarins) |

| Production (width 750 mm): | 7 Tm/h (Oranges); 4 Tm/h (Mandarins) |

| Calibration system: | Tilting rollers in galvanized steel |

| Working Principle: | Progressive separation by gauge, with drop to trays |

| Application: | Citrus fruits and other fruits/vegetables of different sizes |

| Recommended production: | Small productions Fruit |

| Fruit output: | Pick-up trays with direct snap |

| Construction: | Robust metal structure, galvanized steel rollers |

| Online Integration: | Adaptable to low and medium capacity manufacturing processes |

Roller and cord

The cord and roller calibrator is a machine designed for the post-harvest treatment of citrus fruits and other fruits, whose function is to separate the fruit automatically according to its size in a simple and precise way.

The system is composed of a central wheel with two side guides (cords), which open progressively as the fruit advances. This gradual increase in spacing allows each part to fall at the exact point corresponding to its caliber, ensuring uniform sorting and taking care of the product during the process.

It is a compact and efficient equipment, especially suitable for small and medium-sized productions, which offers reliable and low-maintenance calibration in fruit and vegetable plants.

Features

| Installed Power: | 2 Kw |

| Calibration system: | Wheel with progressively opening guide laces |

| Working Principle: | Automatic size separation, gravity-controlled fall |

| Application: | Citrus fruits and other fruits of different sizes |

| Recommended production: | Small and medium-sized productions |

| Fruit output: | Fall into trays or conveyors depending on configuration |

| Construction: | Robust metal frame, easy-to-clean components |

| Online Integration: | Compatible with packaging and packaging processes |