MESH DISC

The mesh disc is a piece of equipment designed for the reception and controlled accumulation of meshes or baskets already made with fruit, keeping them moving by means of a constant rotation.

This system avoids disorderly accumulation at a single point, facilitating pick-up by the operator and optimising the workflow on the packaging line. Its smooth and continuous operation helps to keep the product in good condition, improving efficiency in the final stages of packaging.

It is a compact, reliable and low-maintenance equipment, ideal for integration at the end of the fruit and vegetable packaging line.

FEATURES

| Voltage: | 380/220V III [220V Single Phase On Demand] |

| Main Function: | Reception and accumulation of ready-made meshes or baskets |

| Working System: | Constant spinning keeps product moving |

| Application: | Citrus or other fruit nets and baskets |

| Construction: | Robust structure, easy cleaning and maintenance |

| Online Integration: | Placement at the end of the confection line |

| Main Advantage: | Prevents accumulation at a single point, improves workflow |

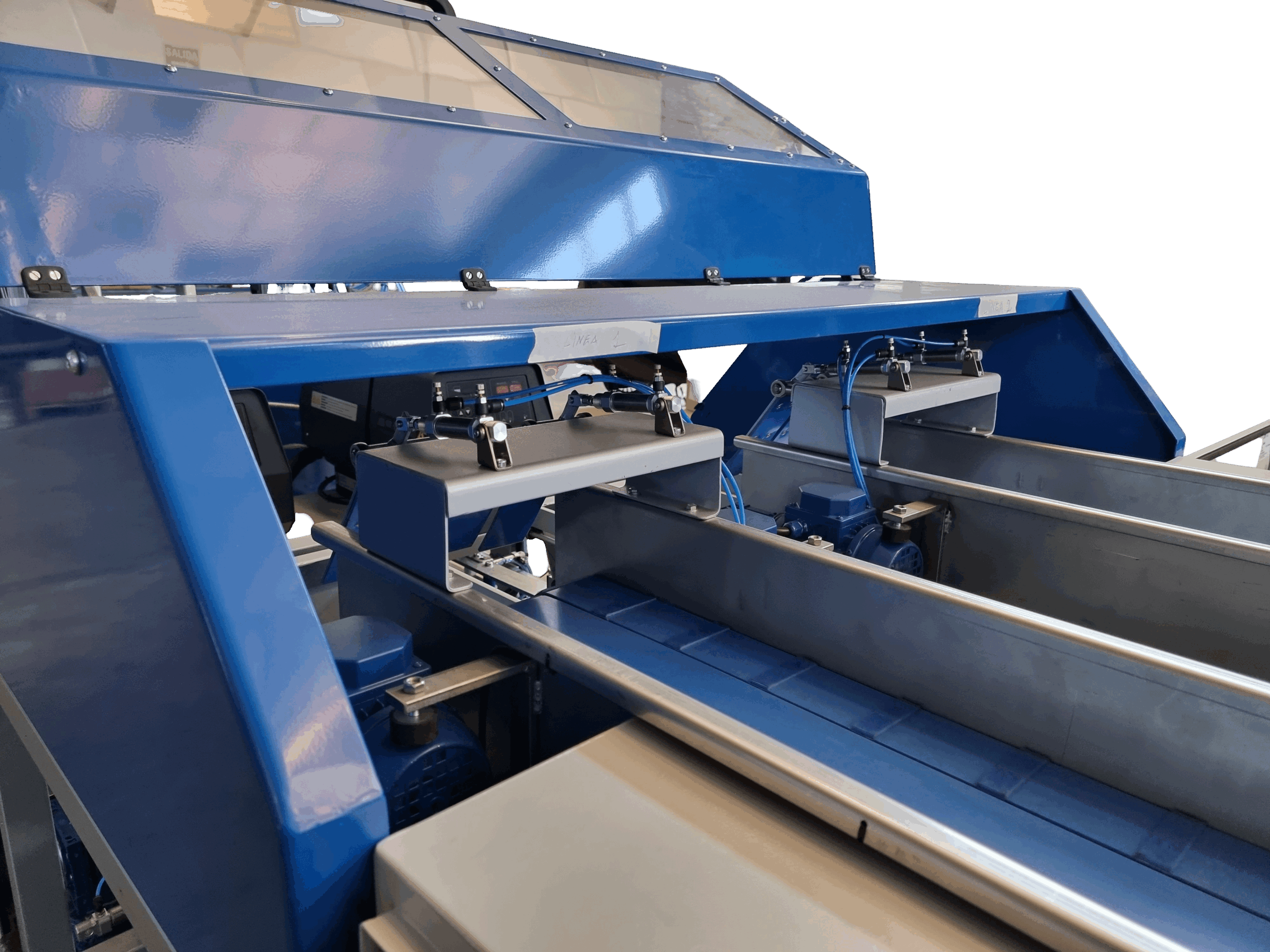

‘PITUFO’ BOX WEIGHER

Machine designed for the post-harvest treatment of citrus fruits and other fruits, designed to automatically weigh and fill smaller format boxes (Pitufo type), guaranteeing precision and agility in the preparation process.

The loose fruit arrives via a double-track upper double conveyor belt:

•A quick-discharge tarpaulin, which provides large quantities of fruit.

•A thin dosage canvas, which drops the fruit piece by piece until the exact weight is reached.

Both belts deposit the fruit in a hopper with a pneumatic opening system, which is located on the box conveyor line. Once the target weight has been reached, the hopper opens to fill the box, which then advances to a vibrator, responsible for settling the fruit inside and improving the final presentation.

The process is completed with a checkweighing by means of a conveyor with an integrated scale, where each box is verified. In case of minimal deviations, an operator can manually correct the filling, ensuring that all boxes meet the required standard.

FEATURES

| Installed Power: | 1.1 Kw |

| Voltage: | 380/220V III (220 V Single Phase Low Drive) |

| Production: | |

| Packaging Type: | Small Smurf Boxes |

| Filling Range: | 0 – 2.5 kg (depending on box) |

| Feeding System: | Double canvas top conveyor (fast + fine dosing) |

| Filling hopper: | With automatic pneumatic opening |

| Box conveyor: | With canvas and vibrator |

| Weight management: | Roller conveyor with integrated scale |

| Precision: | ± 10 – 20 g (depending on product) |

| Recommended fruits: | Citrus fruits (orange, tangerine, lemon) and other small format products |

| Manufacturing material: | Stainless steel and food-grade components |

| Integration: | Compatible with fruit and vegetable packaging lines |

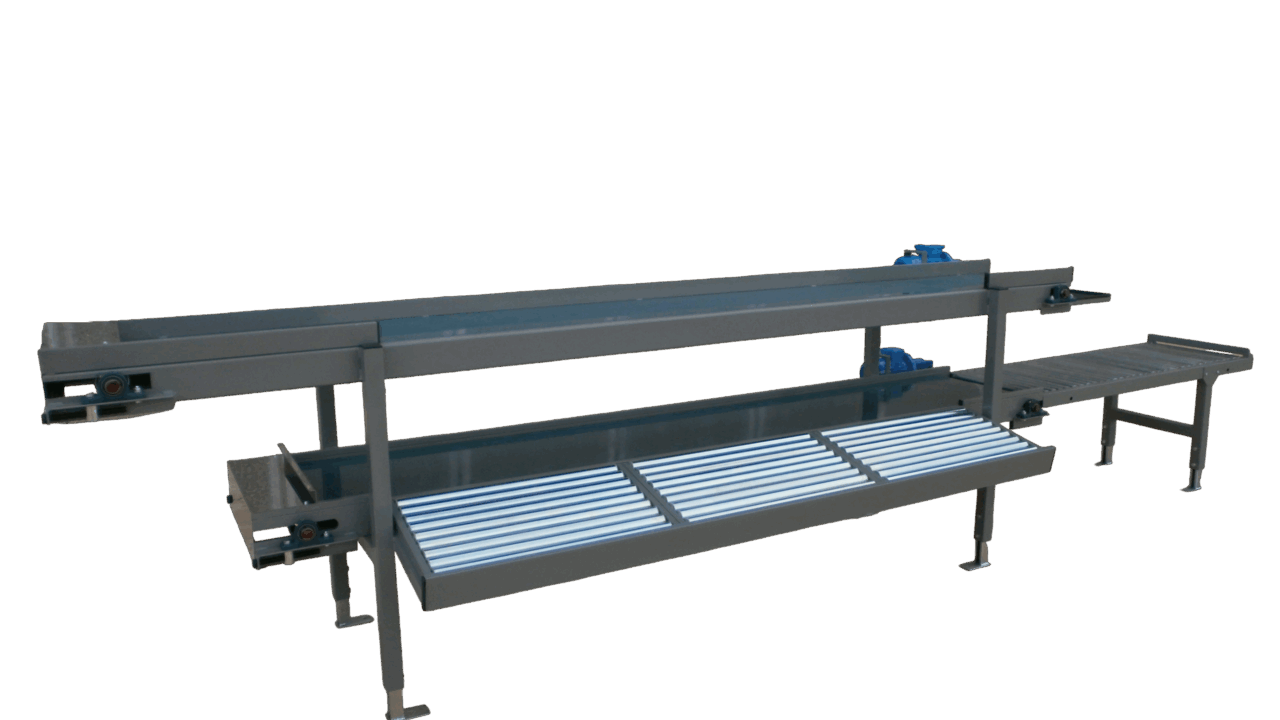

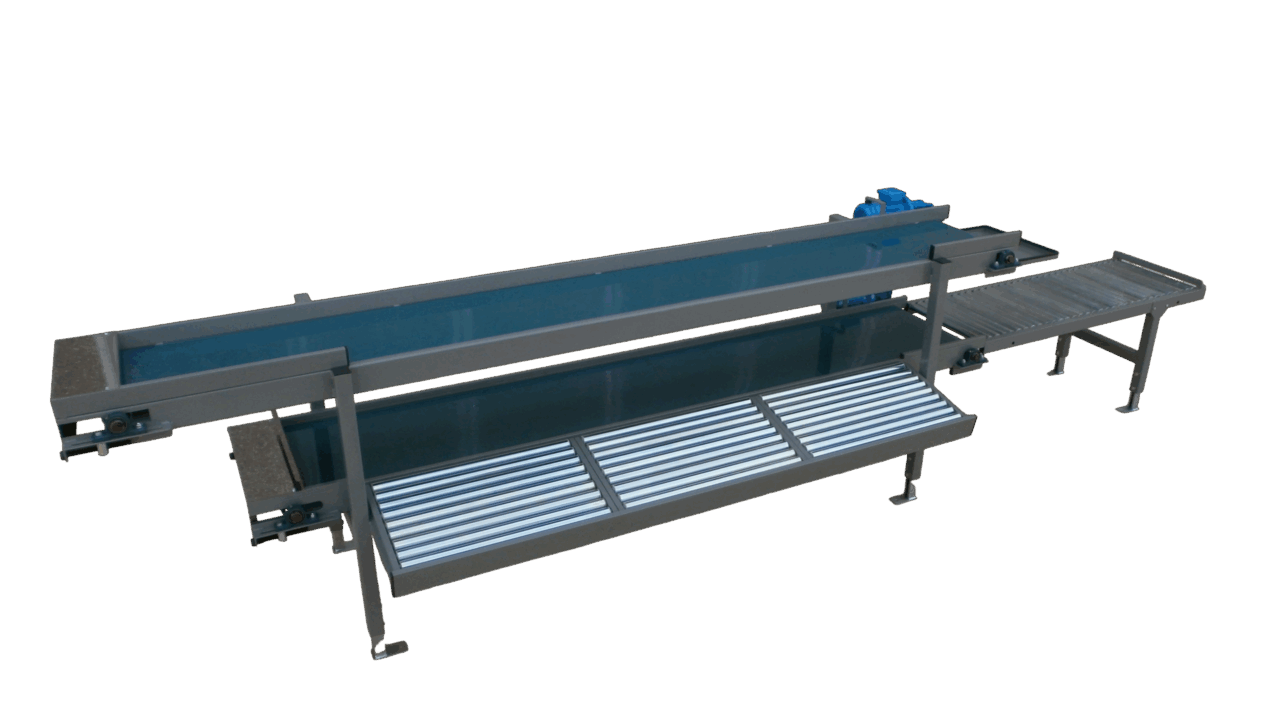

CAMELLO

The Camel is an essential machine in fruit and vegetable packaging lines, specially designed to speed up the filling of boxes with fruit in mesh. Its double conveyor system on two levels allows you to work in a comfortable and orderly way: the upper belt circulates the fruit nets, while the empty boxes ready to be filled are located on the lower part.

The operators take the meshes from the upper belt and deposit them inside the box. Once filled, the box is moved along the rollers by the operator’s own push, until it is incorporated into the lower conveyor, where it continues its journey to the next stages of preparation.

This system stands out for its simplicity, robustness and ease of integration into any line, offering a practical solution for packaging citrus and other fruit in mesh boxes.

FEATURES

| Installed Power: | 1,6 Kw |

| Voltage: | 380/220V III (220 V Single Phase Low Drive) |

| Transport system: | Double conveyor: upper for meshes, lower for boxes |

| Loading area: | Side entry with free rollers |

| Working method: | Manual transfer of meshes to boxes by operators |

| Moving boxes: | Manual by push on rollers |

| Compatible fruit: | Citrus netting (orange, tangerine, lemon, grapefruit) |

| Packaging Type: | Standard boxes or baskets |

| Capacity: | Variable according to caliber, mesh size and number of operators |

| Construction: | Robust metal frame, easy cleaning and low maintenance |

| Online Integration: | Compatible with closure, weighing, labeling and palletizing processes |

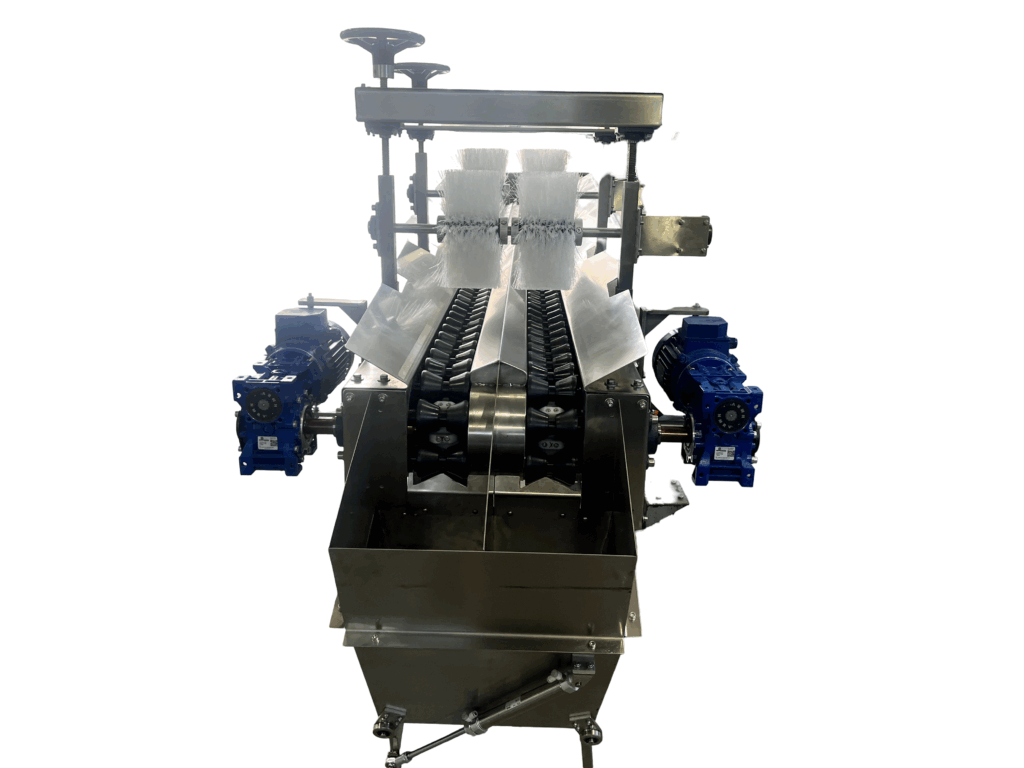

FRUIT COUNTER

The fruit counter is a machine designed to perform an accurate and constant count of citrus fruits. Its two-lane feeding system together with the motorized circular brushes ensures that each fruit advances individually, guaranteeing an even and blockage-free count.

Thanks to this system, the machine allows a record of the total amount of fruit treated and a labelling machine can be integrated to mark each fruit individually, facilitating control in packaging, packaging and order preparation processes.

It is a robust and reliable equipment, adaptable to different sizes of fruit (orange, mandarin, lemon, grapefruit, etc.). In addition, its construction is designed for intensive use, with low maintenance and easy cleaning, which ensures continuous and stable operation.

FEATURES

| Counting System: | Two lanes with individual fruit passage |

| Separating element. | Motorized circular brushes |

| Compatible fruit: | Orange, tangerine, lemon, grapefruit… |

| Capacity: | Gauge and line speed dependent |

| Materials: | Robust metal structure, easy cleaning, stainless steel |

| Online Integration: | Adaptable to packaging and packaging systems |

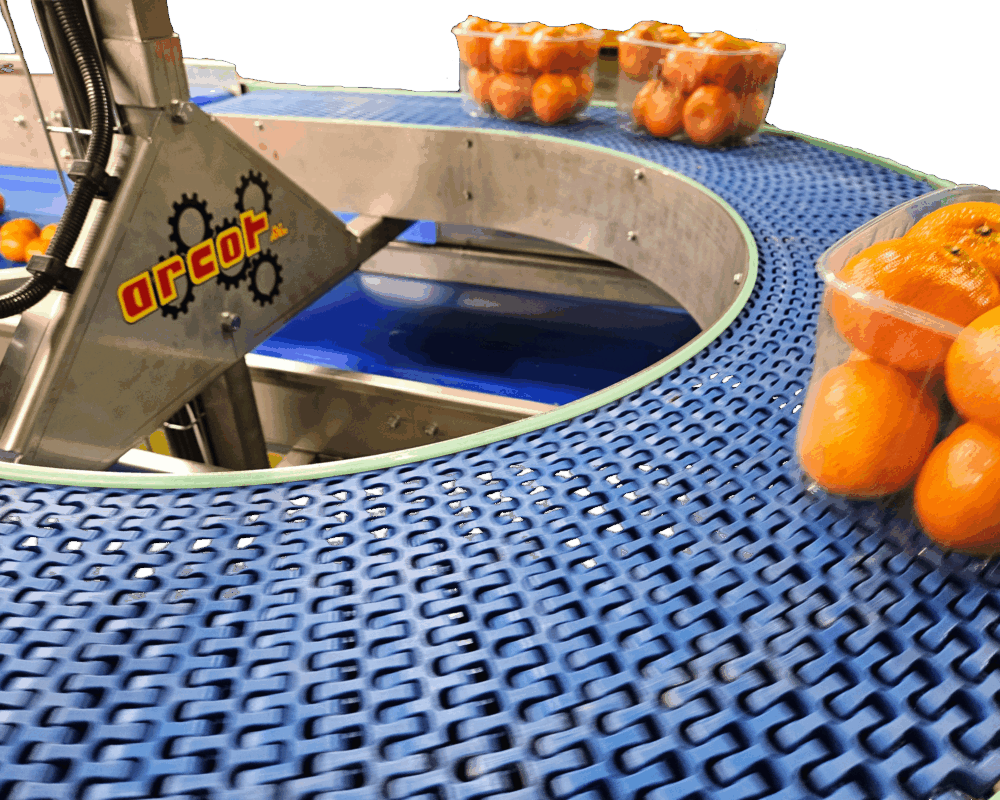

BASKET MAKING MACHINE

The basket making table is designed to facilitate the filling of baskets of different sizes in a uniform and controlled manner. Its system has distribution belts with belts of different direction of advance, which allow the fruit to be distributed homogeneously in each basket, guaranteeing a constant flow and avoiding accumulations.

Its robust and functional construction ensures efficient handling of citrus fruits and other fruits, optimizing the pre-filming process and reducing possible damage to the product during handling. This solution is ideal for packaging lines that require speed, order and precision in packaging.

FEATURES

| Installed Power: | Variable |

| Voltage: | 380/220V III [220V Single Phase on Demand] |

| Other features: | Assembled with a ready-made box output conveyor |

| Main Function: | Facilitate the homogeneous filling of baskets of different sizes |

| Distribution System: | Cast films with different direction of travel |

| Application: | Citrus fruits and other fruits of similar size |

| Construction: | Robust metal structure, easy cleaning and maintenance |

| Online Integration: | Compatible with conveying and filming systems |

| Main Advantage: | Optimizes workflow and reduces damage to fruit |

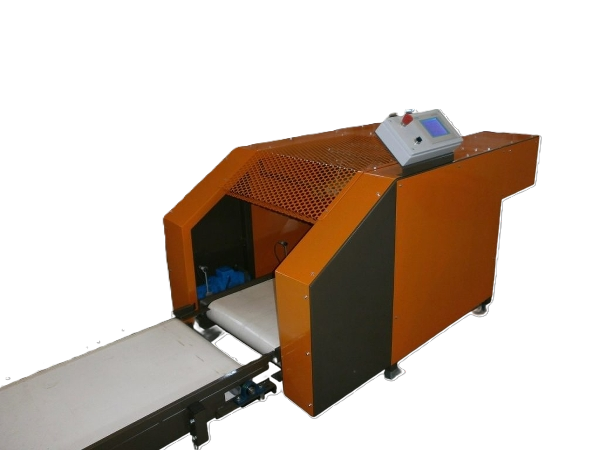

BULK FRUIT FILLER

The bulk fruit filler is designed to automatically fill boxes with fruits of different shapes and sizes, optimizing the workflow on packing lines. Its system combines filling hopper and box conveyor, allowing fast, uniform and safe filling, minimizing damage to the fruit during handling.

Its robust construction and easy to integrate into the line ensures continuous, reliable and efficient operation, adapting to different box formats and production capacities.

FEATURES

| Installed Power: | 1.1 kW |

| Voltage: | 380/220V III [220V single phase on demand] |

| Production: | No production limits |

| Other features: | Filled with boxes of different sizes |

| Main Function: | Automatic bulk box filling |

| Filling System: | Receiving hopper + box conveyor |

| Application: | Citrus fruits and other fruits of different sizes |

| Construction: | Sturdy metal frame and easy cleaning |

| Online Integration: | Compatible with conveyor and packaging systems |

| Main Advantage: | Even, fast and safe filling, minimizing damage to the fruit |

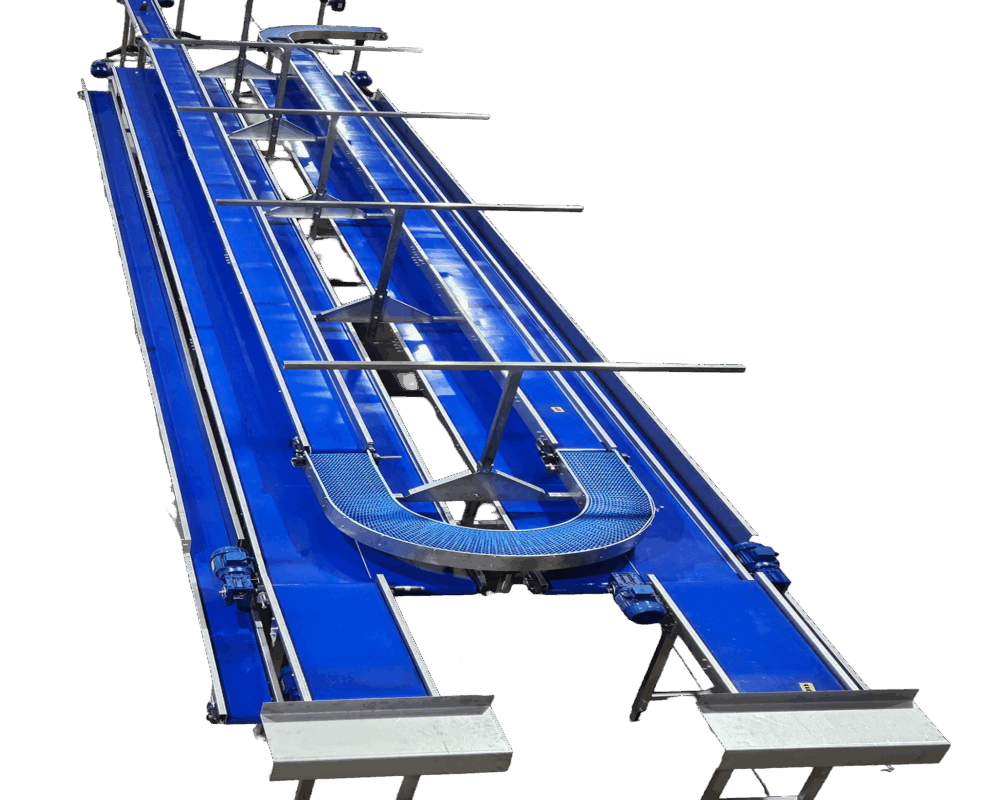

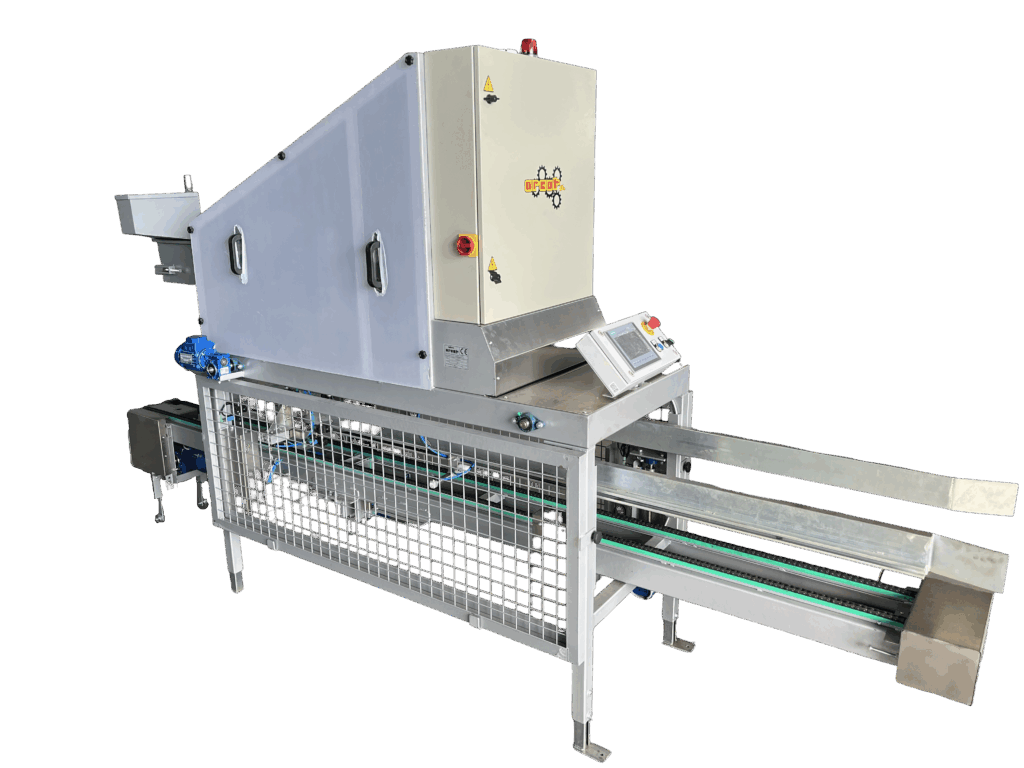

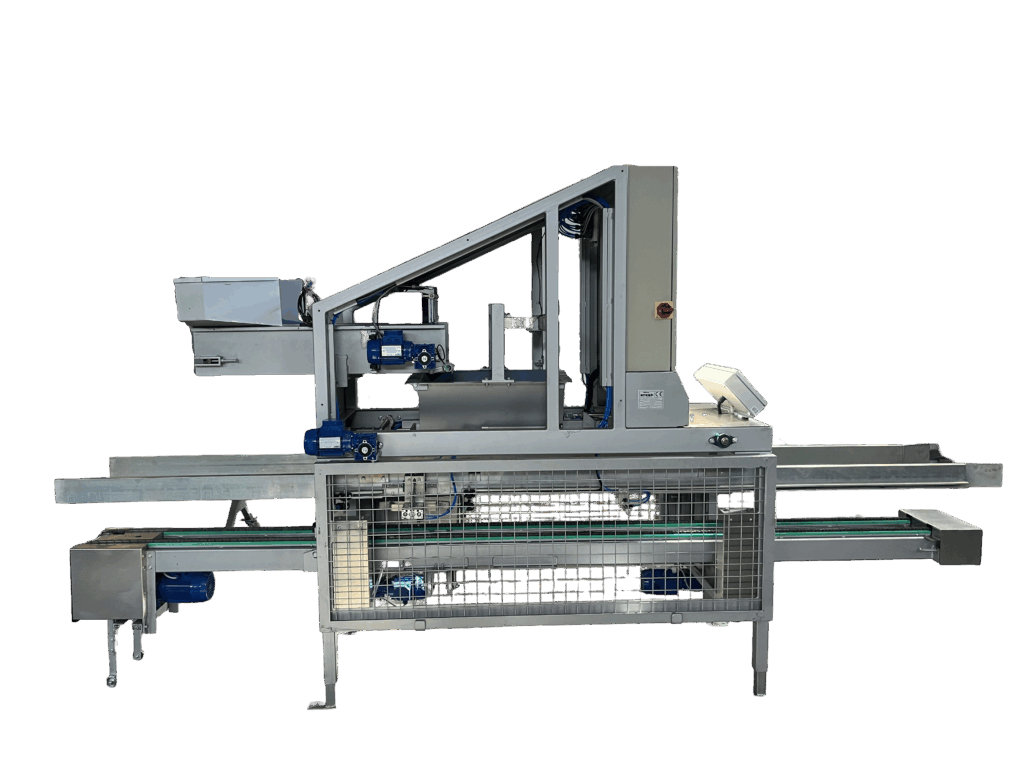

AUTOMATIC FRUIT WEIGHER

Machine for the post-harvest treatment of fruit and vegetables (especially citrus fruits), designed to automatically weigh and fill boxes of different formats, guaranteeing precision and efficiency in packaging.

The loose fruit arrives via a double-track top conveyor belt:

•A quick-unloading tarpaulin, which allows large quantities of fruit to be added at once.

•A thin dosage canvas, which drops the fruit piece by piece until the exact weight is reached.

Both belts deposit the fruit in a hopper with automatic pneumatic opening, located on the lower chain conveyor. It incorporates a lifting system with adjustable arms, which adapts to the dimensions of each box, guaranteeing stability and precision during filling.

Once the process is complete, the box continues to the checkweigher area with integrated scale, where the operator can manually check and, if necessary, correct the fill to ensure that all boxes meet the set weight.

FEATURES

| Installed Power: | 1 kW |

| Voltage: | 380/220V III [220V Single Phase on Demand] |

| Production: | 4 boxes/minute Approx. (depends on the size and density of the product) |

| Other features: | Possibility of box collector in combination with assemblies of several weighers |

| Packaging Type: | Drawers and boxes of different formats |

| Filling Range: | 1 – 20 kg (depending on box) |

| Feeding System: | Top conveyor with discharge belt + fine dosing to hopper |

| Filling hopper: | Automatic pneumatic opening |

| Box conveyor: | Chains, with lifting system and side arms that adjust to the type of container selected + vibrator |

| Weight management: | Integrated scale to check the weight of each box |

| Precision: | ± 20 – 40 g (depending on product and box format) |

| Approximate production: | 300 – 500 boxes/h (depending on the packaging and the type of fruit) |

| Recommended fruits: | Citrus fruits (orange, mandarin, lemon) and other fruit and vegetable products |

| Manufacturing material: | Stainless steel and food-grade components |

| Integration: | Compatible with fruit and vegetable packaging lines |

PACKING TABLE

The packing table is a piece of equipment designed to facilitate the filling of boxes of different sizes quickly and orderly. It has evenly distributed reception hoppers, which allow the fruit to be deposited homogeneously in each box by means of a distributor trolley that guarantees a constant and controlled flow.

Its robust and practical design ensures efficient handling of citrus fruits and other fruits, optimizing the packaging process and minimizing the risk of product damage. It is an ideal solution for packaging lines that require speed, order and precision in order preparation.

FEATURES

| Installed Power: | 1.5 Kw |

| Voltage: | 380/220V III [220V Single Phase on Demand] |

| Other features: | Assembled with a ready-made box output conveyor |

| Main function: | Facilitate homogeneous filling of boxes of different sizes |

| Distribution System: | Receiving hoppers with distributor trolley |

| Application: | Citrus, fruit of similar size and other fruits |

| Construction: | Robust metal structure, easy cleaning and maintenance |

| Online Integration: | Compatible with conveyor and packaging systems |

| Main Advantage: | Optimizes workflow and reduces damage to fruit |

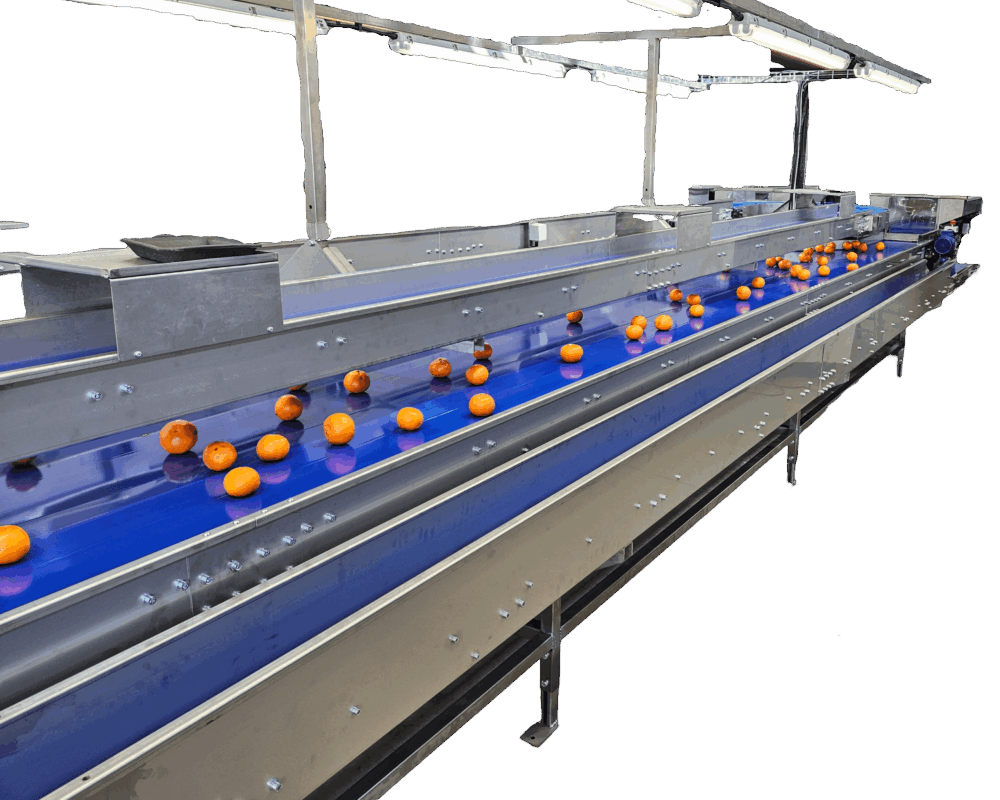

FRUIT ACCUMULATOR

The fruit accumulator is a machine designed to store fruit temporarily and release it in a controlled manner to the next process of the fruit and vegetable line. Its main function is to regulate the flow of fruit, avoiding saturation in the line and allowing continuous and efficient work in fruit and vegetable plants.

The system is composed of two main conveyors:

•A bidirectional accumulation conveyor, capable of working in both directions. In the loading phase, it accumulates the fruit gently; during the unloading phase, it moves it towards the outlet thanks to a central wedge, accompanied by two inclined side tarpaulins that facilitate movement and take care of the product during the process.

•A short extraction conveyor, located at the outlet, which collects the fruit delivered by the accumulation and leads it in a regulated manner to the next destination on the line.

Made of iron or stainless steel, the lung can be adapted in capacity and dimensions according to the customer’s requirements, always guaranteeing careful and efficient handling of the fruit.

FEATURES

| Installed Power: | 0,55 Kw |

| Voltage: | 380/220V III [220V Single Phase on Demand] |

| Capacity: | 200 Kg |

| Machine Type: | Fruit accumulator and dosing lung |

| Main Function: | Temporary accumulation and regulated dosing |

| Accumulation system: | Two-way wedge tape + slanted side tarps |

| Extraction system: | Short discharge belt |

| Construction: | Painted iron or stainless steel |

| Application: | Loose fruit (citrus fruits, fruits and vegetables) |

| Integration: | Compatible with calibrators, washing machines and packaging lines |

| Customization: | Dimensions and capacity adjustable to each project |

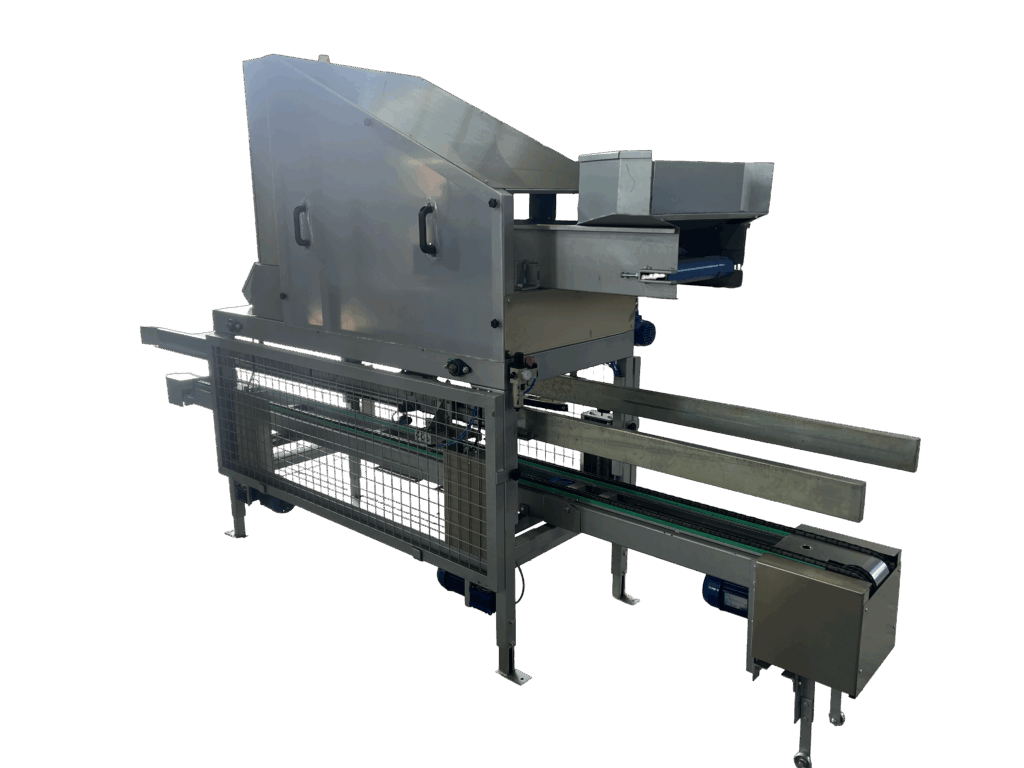

BIN FILLER WEIGHER

The Bins filler and weigher is a machine designed for the automatic filling and weighing of large capacity containers (Bins), guaranteeing a fast, efficient process with the utmost care for the product.

Its system incorporates a mobile unloading conveyor, which distributes the fruit evenly inside the container, avoiding blows and ensuring delicate treatment throughout the process. The integrated weight control allows the amount of fruit in each Bin to be precisely adjusted, optimising product management in fruit and vegetable centres.

This equipment is characterized by its robustness, reliability and ease of integration into post-harvest lines, offering a practical solution for the storage and logistics of citrus fruits and other fruits.

FEATURES

| Installed Power: | 1,6 Kw |

| Voltage: | 380/220V III [220V Single Phase on Demand] |

| Output: | 3600/4300 Kg/h |

| Main Function: | Automatic Filling and Weighing of Bins |

| Discharge system: | Mobile conveyor for better fruit distribution |

| Weight management: | Precision adjustable as required |

| Application: | Citrus and other post-harvest fruits |

| Construction: | Robust and easy-to-clean metal structure |

| Online Integration: | Supports picking, calibration, and storage processes |

| Main Advantage: | Maximum fruit care and filling optimization |