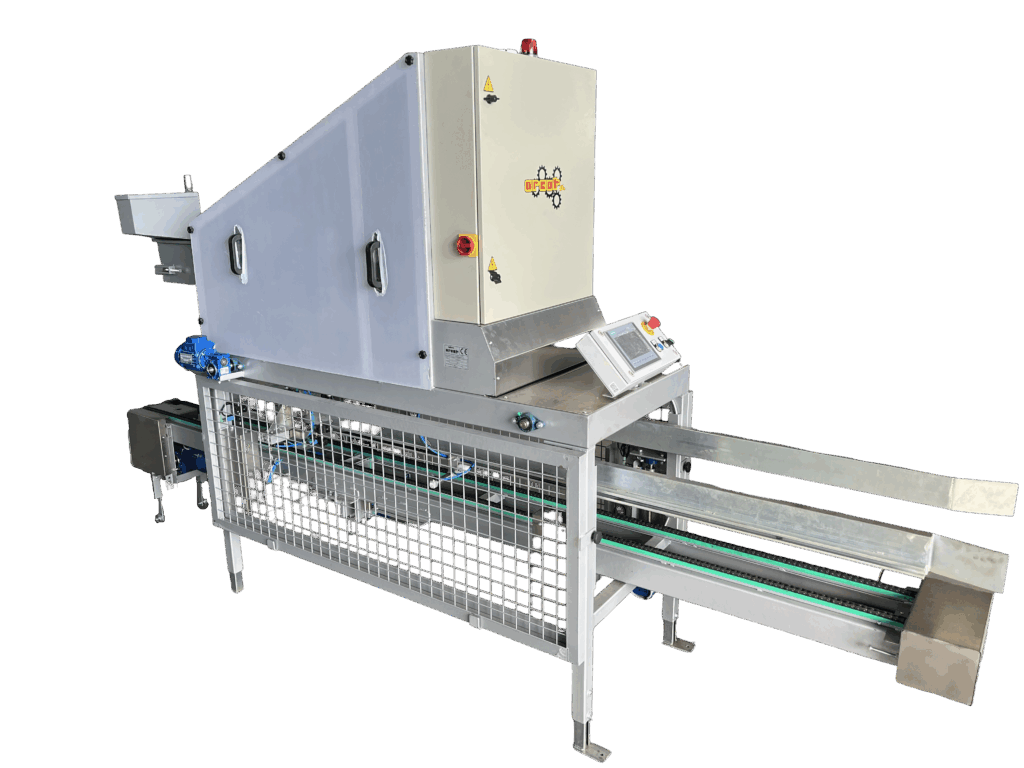

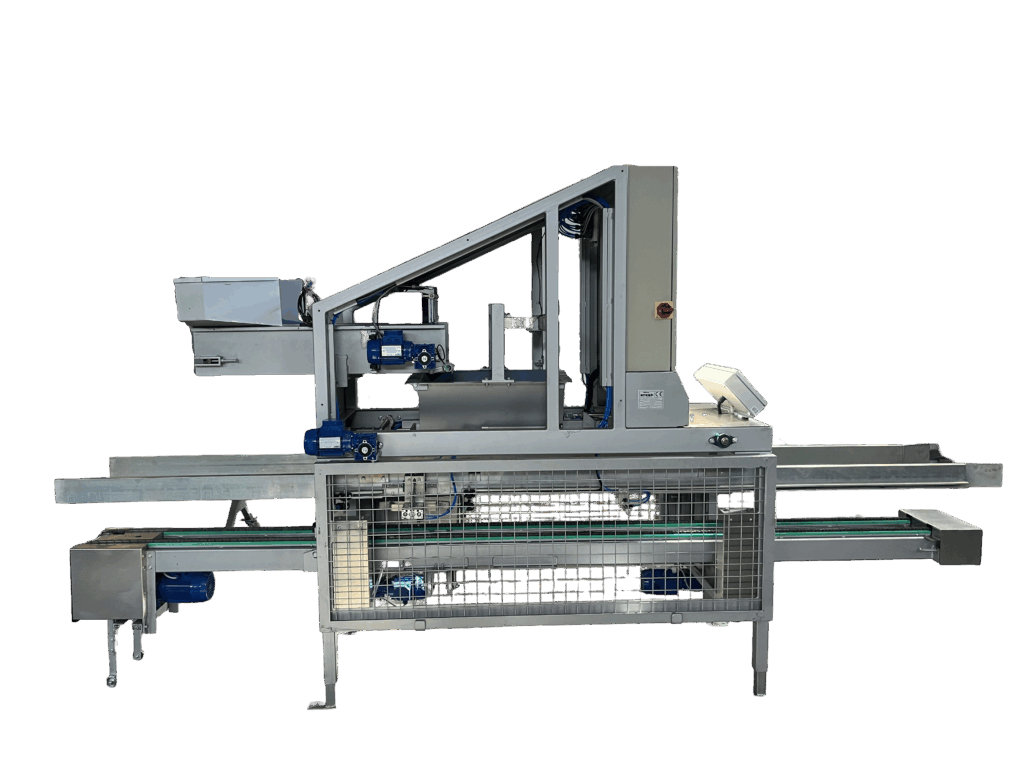

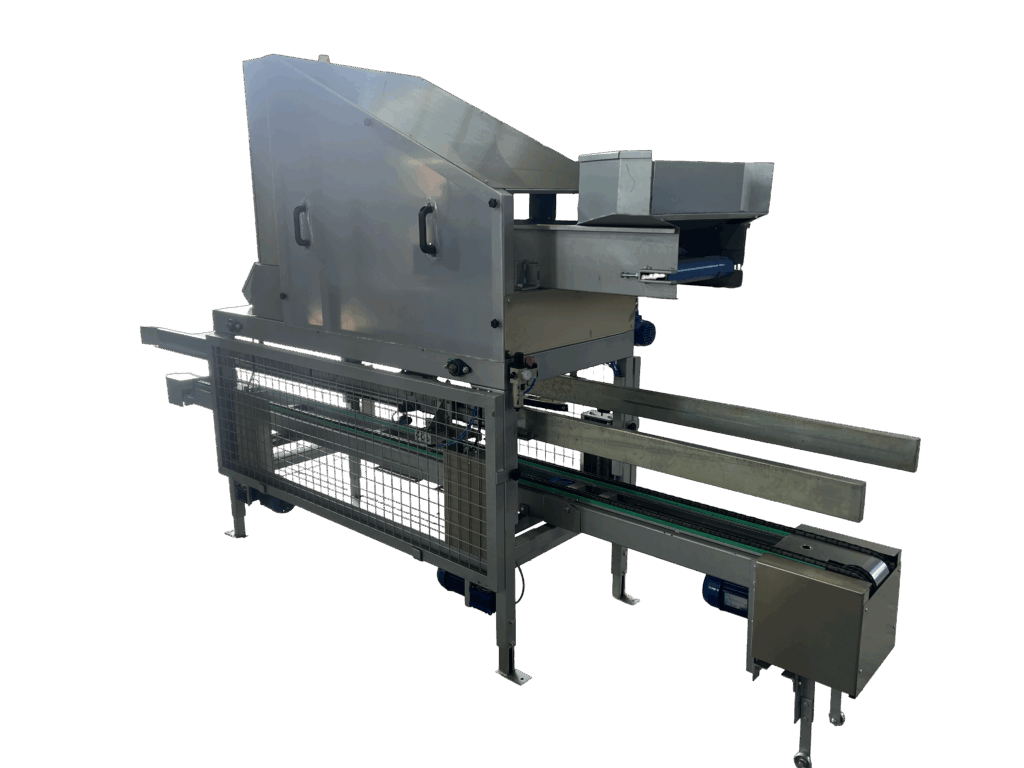

AUTOMATIC FRUIT WEIGHER

Machine for the post-harvest treatment of fruit and vegetables (especially citrus fruits), designed to automatically weigh and fill boxes of different formats, guaranteeing precision and efficiency in packaging.

The loose fruit arrives via a double-track top conveyor belt:

•A quick-unloading tarpaulin, which allows large quantities of fruit to be added at once.

•A thin dosage canvas, which drops the fruit piece by piece until the exact weight is reached.

Both belts deposit the fruit in a hopper with automatic pneumatic opening, located on the lower chain conveyor. It incorporates a lifting system with adjustable arms, which adapts to the dimensions of each box, guaranteeing stability and precision during filling.

Once the process is complete, the box continues to the checkweigher area with integrated scale, where the operator can manually check and, if necessary, correct the fill to ensure that all boxes meet the set weight.

FEATURES

| Installed Power: | 1 kW |

| Voltage: | 380/220V III [220V Single Phase on Demand] |

| Production: | 4 boxes/minute Approx. (depends on the size and density of the product) |

| Other features: | Possibility of box collector in combination with assemblies of several weighers |

| Packaging Type: | Drawers and boxes of different formats |

| Filling Range: | 1 – 20 kg (depending on box) |

| Feeding System: | Top conveyor with discharge belt + fine dosing to hopper |

| Filling hopper: | Automatic pneumatic opening |

| Box conveyor: | Chains, with lifting system and side arms that adjust to the type of container selected + vibrator |

| Weight management: | Integrated scale to check the weight of each box |

| Precision: | ± 20 – 40 g (depending on product and box format) |

| Approximate production: | 300 – 500 boxes/h (depending on the packaging and the type of fruit) |

| Recommended fruits: | Citrus fruits (orange, mandarin, lemon) and other fruit and vegetable products |

| Manufacturing material: | Stainless steel and food-grade components |

| Integration: | Compatible with fruit and vegetable packaging lines |